MOST OF WHAT YOU NEED TO KNOW ABOUT

All about plywood and lumber (well most). From where to get it, what kinds to use and even how much it costs.

I highly suggest that you take the time to at least glance over this page, for I feel it contains a good deal of useful information that any ramp builder should be familar with.

If you aren't going to read past this paragraph, at least know this... do not use particle board, the size of lumber varies outside of America and pressure treated wood contains nasty chemicals.

PLYWOOD

Plywood is a manufactured wood that takes plys of veneer and glues them together with alternating grains. Meaning that one layer has the grain running lengthwise and the next layer has the grain running widthwise. They are usually made with odd number of plys to resist warping.

In America, plywood is generally sold in sheets that are 4 x 8 feet and available in many different thicknesses and species of wood. Outside of the US, the sheets are slightly smaller at 1.2 x 2.3 meters. All plywood referenced within this site (at this time) will be in the American size of 4 x8 feet.

To construct a sheet of plywood, the manufacturer takes sheets of veneer and presses them with a particular type of glue to make whatever thickness of plywood is needed. The quality of wood dictates how strong and durable the plywood is. For instance, birch has phenomenal surface hardness, therefore birch plywood is one of the best. And a great choice as the riding surface for many indoor ramps.

The plywood that we are concerned with are given grades, but only in the Unites States. The grades are indicated by a letter and tend to be complicated, so I am going to try and cover them in depth.

These grades are...

- The highest grade of plywood. Always sanded smooth with all knots, splits and cracks filled with a plug or man made wood material.

- Solid wood surface with minimal, small diameter knots and thin splits which have mostly been filled. This grade is usually sanded smooth.

- Not as nice as B grade, this grade has knots up to 1 1/2" in diameter and a few cracks or splits providing that the strength is not compromised.

- Some manufactures plug the knots, splits and cracks and this is known as C Plugged grade.

- This is the lowest grade of plywood and can have many splits and cracks as well as knots up to 3" in diameter. The surface is left as is with all the imperfections and discoloration intact. You should try to avoid using this grade outdoors.

Most plywood is described using more than one letter. The first letter indicates the face ply or top ply, while the second letter references to the bottom ply. Often, the letter "X" is added to describes the center plys as being made up of scrap wood.

An example of this would be CDX plywood. Meaning that the face ply "C" is of decent quality with minimal knots which have sometimes been filled, the bottom ply "D" is of poor quality and the center plies "X" are made up of scrap wood. This is not a bad choice for structural use, like the side templates of a ramp.

Another example, BC plywood. Which has a face ply "B" that is of good quality and the bottom ply "C" that has few knots or other imperfections. This grade is good for decks and structural as well.

There's also birch plywood, Finnish birch in particular that is excellent for indoor skateboard ramp construction. Team Pain regularly builds their indoor wooden parks with this as their top layer. However it is expensive and sometimes difficult to find.

LUMBER

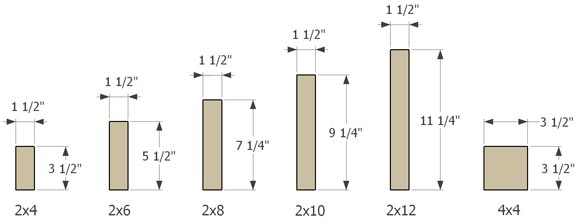

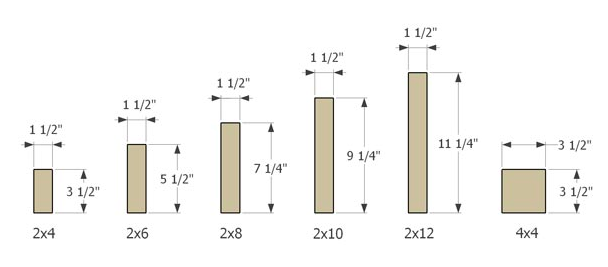

Dimensional lumber, like a 2x4 for example is not actually 2 by 4 inches. This is referred to as Nominal (what they call it) and Actual (what it is) size. Most of you probably know this, but for those who don't or would like a cheat sheet, here's a breakdown of dimensional lumber and it's actual dimensions.

Most dimensional lumber outside of North America differs from what is listed here.

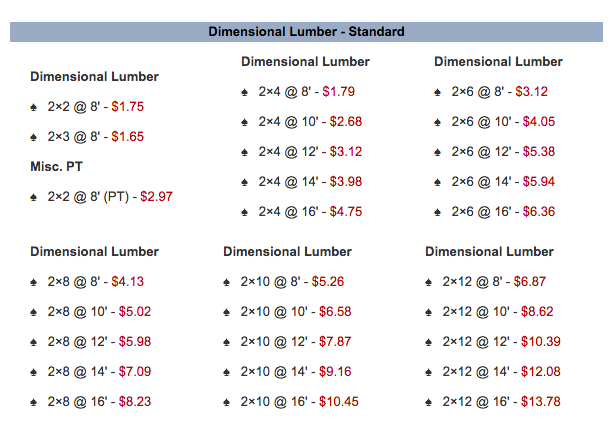

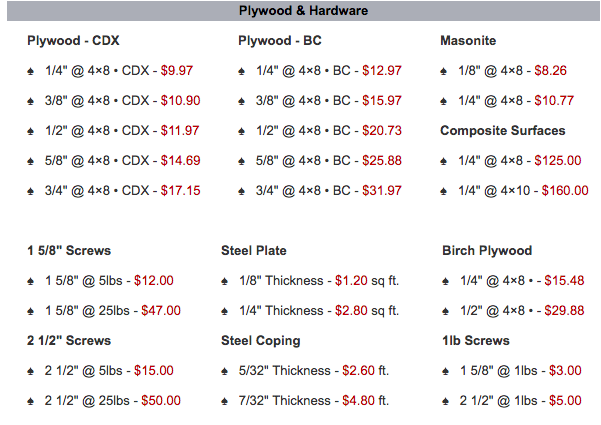

APPROXIMATE COST

The price of lumber changes often and will seldom be the same price where I live and where you live.

That said, I still need to estimate the cost of the projects within these pages so you can budget before you start to build. I do that by going to different lumber supply stores and writing down their costs. Once I've done that, I average them among the other suppliers. This provides me with a base cost which I add hardware cost and a margin of about 5 %. Tool and labor costs are not included.

Here is a (horribly outdated) copy of the prices which I've obtained...

STANDARDS

When you build, it's best to build in sizes that are the same as common wood dimensions. For example, plywood is purchased in 4x8 sheets (for the most part). So these plans will reflect that. This makes it much easier to build, saves a lot of wood waste and conserves money, which is always good.

NOTE: Unfortunately outside of the US, wood is purchased in a different size than what is listed here. I hope to someday include sizes, dimensions and the metric system within these pages. But that is just not possible at this time.